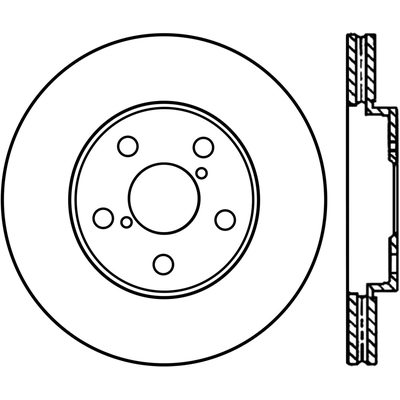

Centric Premium brake rotors are double-disc ground and have a taper-free finish that ensures parallelism, eliminates run out, and provides near-perfect disc thickness variation (DTV). Double disc grinding leaves a non-directional finish on the rotor surface that provides an effective pad-rotor break-in and quieter and smoother stops. Centric premium rotors are machined finish, including rotor hats that provide better rotor balance and a have a more aesthetic finish. Additionally, Centric Premium rotors are balanced and mill-corrected to a tolerance of less than 2 oz. inch. This reduces rotor vibration and provides a smooth and confident brake application.

Centric Premium brake rotors feature symmetric vane castings for increased heat transfer and thermal efficiency, which offers superior braking power and safety. This means you can get consistent braking performance even during repeated braking like in a stop-and-go traffic condition. Centric Premium brake rotors feature OE-style vane designs that ensure OE function and performance. Centric premium rotors are electro-statically E-coated, which allows the rotors to withstand 400 hours of saltwater exposure without rusting so you do not have to worry about brake rotor rust during winter seasons. Centric's e-coating is also more effective than competitor phosphate-finished rotors that offer minimal protection from the elements and are therefore more vulnerable to rusting especially in humid and salty road conditions.